From Chaos to Clarity: How an Engineering Firm Cut Manual Work with an AI Portal

What happens when your best people spend more time fixing spreadsheets than managing projects? That was the daily reality for one engineering company, until automation gave them back their time.

The firm was managing dozens of active projects at once. Each coordinator handled 15–20 projects across multiple platforms, ConnectTeam, Excel, VantagePoint, SharePoint, and Lab systems, with no direct connection between them.

Every new project meant opening different tools, copying data across spreadsheets, and replying to dozens of client emails that arrived in fragments.

By the end of each day, inboxes were stacked with 60+ unread messages, many with missing attachments or unclear instructions.

“We weren’t slow… we were buried.”

The result?

Invoices are delayed by days or weeks.

Hours lost to repetitive data entry.

And a growing sense that the company’s people were working harder than ever — but getting less done.

The problem wasn’t productivity. It was a process.

The Discovery: Manual Work Isn’t the Problem

When ScaleLabs began analyzing the company’s operations, the pattern became clear: the real bottleneck wasn’t human effort. It was a patchwork of disconnected systems.

Across the board, the same issues kept surfacing:

Coordinators spent hours re-entering data that already existed elsewhere.

Critical details lived in separate tools, forcing constant tab-switching.

Email had become the default project management system, and it was breaking under the pressure.

It wasn’t that the team was underperforming.

The workflow itself was outdated. Designed for a smaller business that had outgrown its tools.

That insight reframed the challenge completely. The goal wasn’t to do more work. it was to stop doing the same work twice.

The Solution: A Unified AI-Powered Portal

ScaleLabs developed a centralized, AI-enabled project portal that merged the firm’s disconnected tools into a single, automated workflow.

Here’s how it worked:

ConnectTeam schedules are synced automatically into one dashboard.

Timesheets from VantagePoint are updated in real time.

Lab reports, field data, and invoices were linked directly to the corresponding projects.

AI validation flagged missing information, duplicate entries, or mismatched data before submission.

Instead of juggling five different tools, coordinators now open one. Project data flowed seamlessly between systems, approvals were instant, and every team member, from field technicians to project leads, saw the same live information.

The change didn’t just improve visibility; it restored control. No more version confusion. No more waiting for manual uploads. Just one connected system that kept projects moving.

From Inbox Chaos to Smart Requests

Email had quietly become one of the biggest productivity drains. Every client request turned into a chain of follow-ups. “Can you resend that file?”, “Which project was this for?”, “Who’s handling this one?”

The new portal fixed that with guided web forms.

Instead of sending emails, clients now submit structured requests online, complete with attachments, project details, and timelines. Each request automatically enters the portal, assigns itself to the right project, and alerts the correct coordinator.

No more missing attachments.

No more lost context.

No more inbox chaos.

Within 90 days, over 80% of all client communication moved from email to portal, cutting admin time in half and giving coordinators hours back every week.

For the first time, everyone, clients, coordinators, and leadership, operated from the same source of truth.

One Dashboard to Rule Them All

Before automation, the company’s data was split between five different systems: ConnectTeam for scheduling, VantagePoint for timesheets, JotForm for field reports, SharePoint for billing, and a lab database for testing records. Every update meant copying, exporting, importing, and emailing the same information across tools.

The new portal changed everything. Through modern API integrations, all five systems now connect seamlessly, creating one unified, live dashboard where every update happens automatically.

Scheduling pulls in from ConnectTeam in real time.

Timesheets update instantly from VantagePoint.

Lab results and reports are attached directly to each project.

Documents sync automatically with SharePoint, no manual uploads.

For the first time, everyone - from field teams to executives - sees the same version of truth. No duplicate files, no lost updates, no “Which spreadsheet is latest?” conversations.

What used to take five tabs, ten steps, and two people now takes one click.

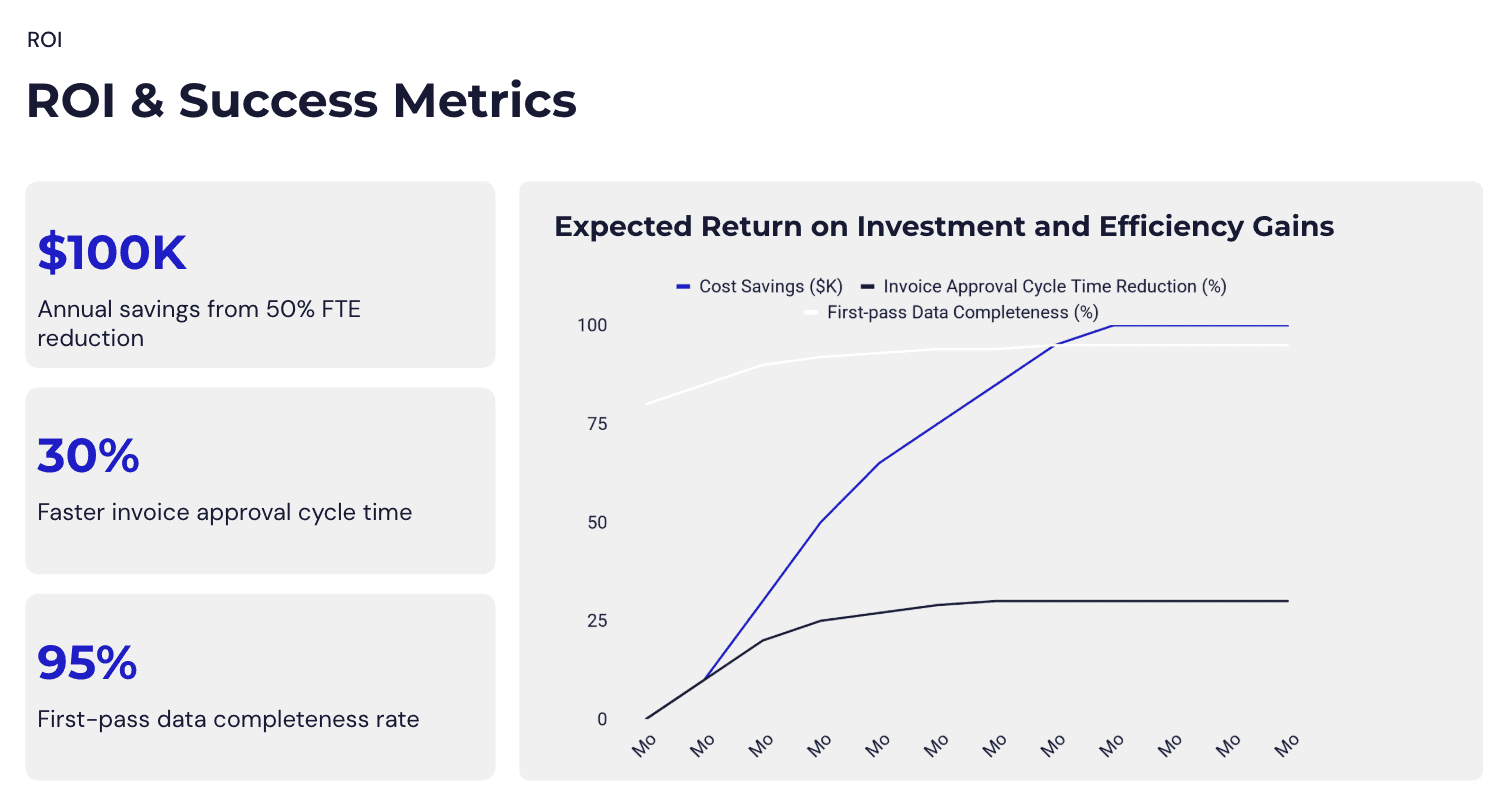

The ROI: Time Saved, Accuracy Gained

Once the system went live, the impact was immediate and measurable. Administrative chaos turned into operational rhythm.

Here’s what the numbers showed:

50% reduction in manual admin time across the coordination team.

60% faster billing and approval cycles.

$100,000+ annual savings through efficiency gains and fewer errors.

But the real ROI went beyond numbers. Project coordinators finally had breathing space to focus on what mattered: supporting clients, improving processes, and managing field quality instead of managing spreadsheets.

Clients noticed the difference too: faster responses, clearer communication, and transparent access to project updates through the portal. It wasn’t just automation; it was a cultural shift from reactive to proactive operations.

The Future of AI in Engineering Operations

For the company, this wasn’t just a technology upgrade; it was a mindset change. What started as a way to automate manual work evolved into a foundation for AI-assisted project management.

With clean, connected data now in one place, new possibilities opened up:

Predictive workload balancing for field technicians.

Automated flagging of cost overruns before they happen.

Real-time performance analytics across projects.

The goal is no longer just saving time. It’s making smarter decisions faster.

AI isn’t replacing people; it’s replacing the work that slows them down.

For engineering and construction teams facing similar challenges, this transformation is proof that operational excellence doesn’t come from adding more systems. It comes from uniting the ones you already have.

Final Takeaway

Every growing company hits a breaking point, where great people are held back by outdated systems. This engineering firm didn’t need more staff, new departments, or endless training sessions. It needed a smarter way to work.

By connecting its tools, automating repetitive tasks, and integrating AI into everyday workflows, it turned chaos into clarity and reclaimed the time, accuracy, and confidence that modern operations demand.

The lesson is simple:

You can’t scale manual work. But you can scale systems that think for you.

If your team is stuck in the same cycle, juggling spreadsheets, chasing approvals, and losing hours to admin. It might be time to rethink your foundation.

Ready to see what’s possible?

ScaleLabs builds custom AI-powered platforms that help engineering and construction firms move faster, work smarter, and eliminate manual chaos for good